Ball valves and butterfly valves have several characteristics in common and so can be used for many similar applications. So why choose one over the other?

Pretty much everyone knows that a ball valve consists of a ball with a hole through it. A butterfly valve consists of a disk mounted on a rotating shaft.

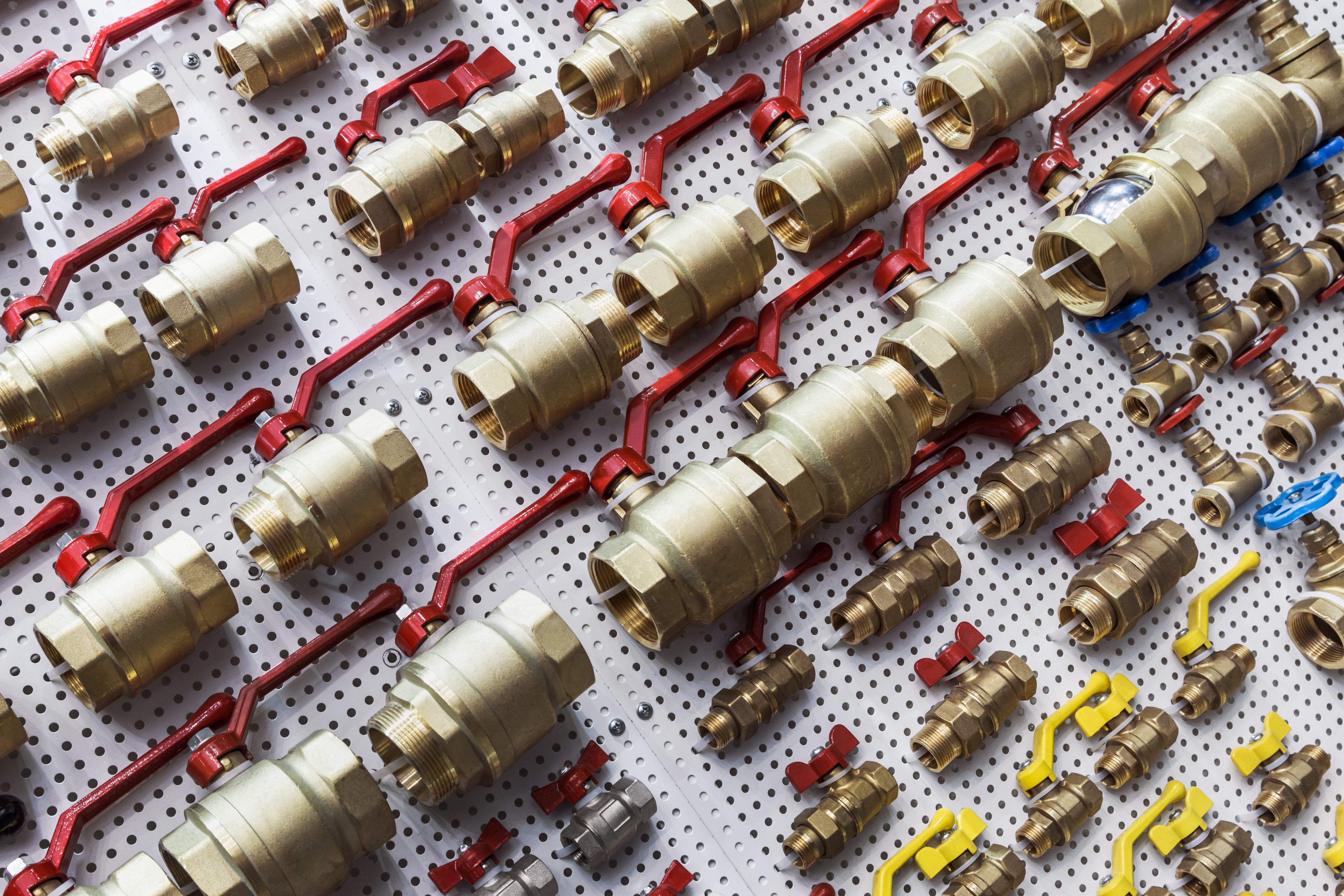

They’re both quarter-turn rotary valves, requiring a 90-degree turn from open to close. Both are typically made from a combination of cast iron, stainless steel and brass. Each is effective for regulating the flow of most types of gas and liquid at a wide range of temperatures. And they're both relatively inexpensive, long-lasting and dependable.

Why choose ball valves?

One of the advantages of a ball valve is that it will almost always turn, regardless of the amount of pressure being placed on it from the supply side. Once open, there is rarely a drop in pressure because the hole in the ball allows 100 percent of the gas or liquid to flow.

Butterfly valves are built so that part of the disk is always interfering with the flow of the liquid or gas. This means there will always be a pressure drop when using a butterfly valve. It also means that butterfly valves can be difficult to open and a bypass valve may be necessary to create balance in the lines before large butterfly valves can properly operate. Ball valves seal more effectively than butterfly valves, so ball valves are generally better for projects involving the flow of gas.

Why choose butterfly valves

Butterfly valves are small and, when actuated pneumatically, open and close very quickly. The disc is lighter than a ball, and the valve requires less structural support than a ball valve of comparable diameter. Butterfly valves are very precise, which makes them advantageous in industrial applications in particular. They are also reliable and require very little maintenance.

Butterfly valves are generally less expensive to build and maintain, so they’re frequently used in large-scale municipal water and sewer projects. They are also common for projects that control the flow of river or stream water.

Ball valves and butterfly valves are both versatile, relatively inexpensive and able to stand the test of time. Selecting the right one depends on the size and scope of the task. For help determining whether a project calls for a ball valve or butterfly valve, or another type of valve, we're always here to help.